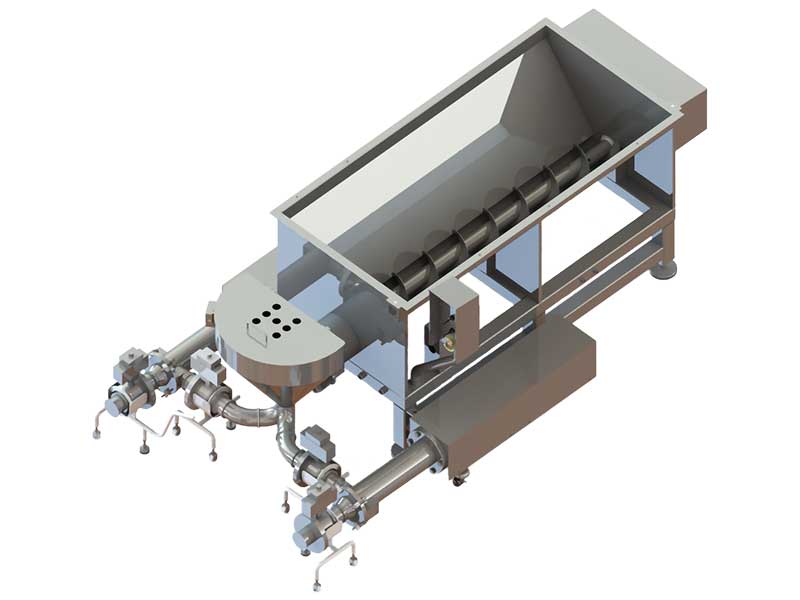

Continuous Transfer Device "Auger Feed Hopper"

Transfers products smoothly to the next process while maintaining quality.

Higashimoto Kikai's Auger Feed Hopper continuously transfers products from the previous process to the next stage.

The inverter control enables optimal rotation speed, ensuring quality maintenance during transfer.

- Easy disassembly of screw shaft seal for daily cleaning

- Equipped with inverter control

- All-stainless steel frame

- Transfer method customizable (rotary pump, piston pump, etc.)

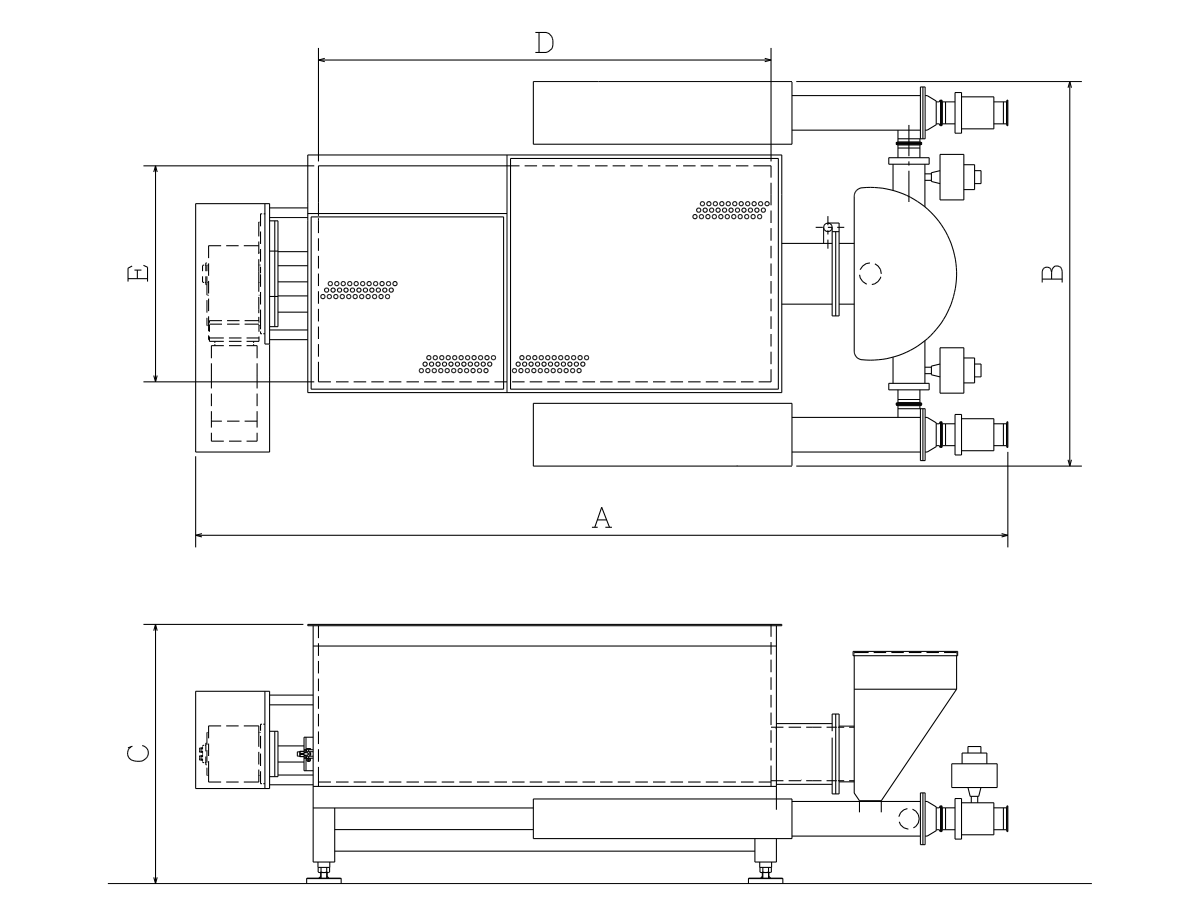

SPECIFICATIONS

| Hopper capacity | A | B | C | D | E | Electric capacity (kW) |

|---|---|---|---|---|---|---|

| 600L | 3770 | 1780 | 1200 | 2100 | 1000 | 2.2kW |

| 2000L | 4580 | 1860 | 1200 | 3370 | 1000 | 2.2kW |

- All stainless steel construction (SUS304)

- Screw drive: Inverter-controlled

- Transfer method: Rotary pump / Piston pump

- Load cell (optional), cleaning unit (optional)

- Transfer method and hopper capacity can be customized to meet customer specifications.

All specifications can be changed to suit your needs. Please feel free to contact us!

YouTube Video